Fluorescent Inks And Powders

Fluorescent inks are more sensitive and therefore they can detect smaller, finer discontinuities.

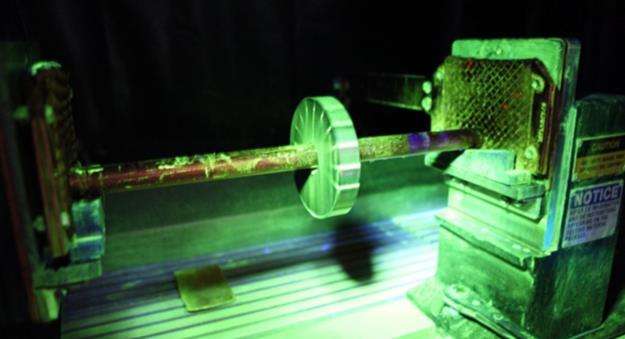

The area under inspection should be irradiated with UV-A light. The levels of UV-A irradiation are quoted in the relevant standards together with the maximum permitted background illumination and are checked/quantified using UV-A light meters called radiometers.

BS EN ISO 9934-1 refers to BS EN ISO 3059 for UV-A conditions which quotes a minimum UV-A

irradiance of 1000 µW/cm2 (1.0mW/ cm2) and a maximum 20 lux ambient background lighting.

Most aerospace process specifications require the use of fluorescent ink and a UV-A irradiance of

1200µW/cm2 with 20 lux ambient visible light.

Note: Fluorescence is the absorption of a short invisible wavelength and remitting this at a longer wavelength in the visible part of the electromagnetic spectrum. This should not be confused with a materials ability to glow, known as phosphorescence, where a material is charged by exposure to light and releases this energy slowly. This is a very different process to that which takes place in MT detecting media.

Fluorescence degrades with exposure to ordinary light over a period of several hours, moreover, it can be arrested entirely at high temperatures. As the intensity of the ultraviolet light is increased, the amount of fluorescence increases.

A minimum light adaptation period of up to 5 minutes prior to inspection may be required whilst most aerospace specifications only quote 1 minute for light adaptation to the inspection area.